3D printing in custom fashion manufacturing: a new era

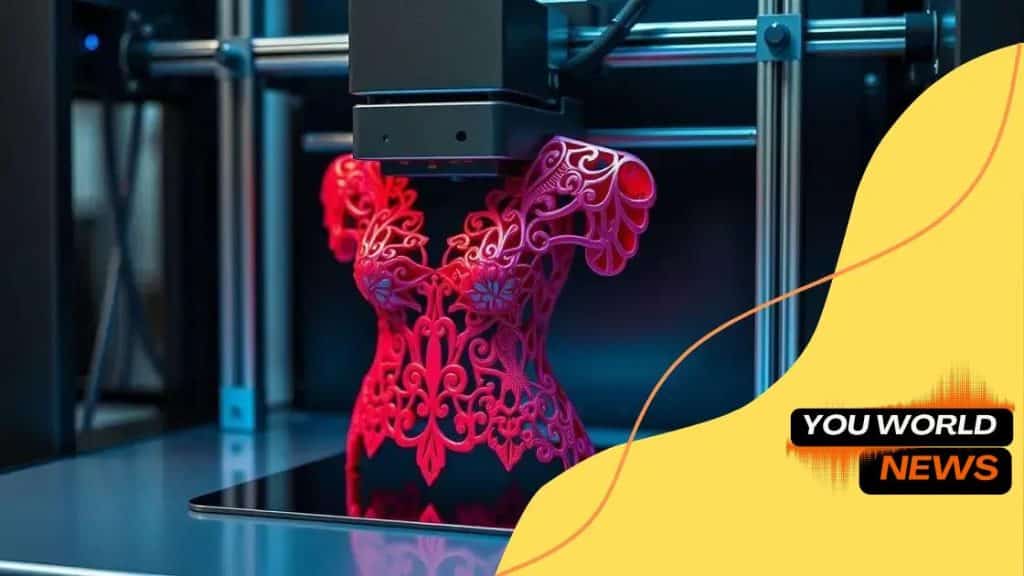

3D printing in custom fashion manufacturing revolutionizes the industry by enabling personalized designs, reducing material waste, and enhancing sustainability through on-demand production and innovative materials.

3D printing in custom fashion manufacturing is reshaping the landscape, offering unique opportunities for creativity and personalization. Have you ever imagined wearing something truly one-of-a-kind? This technology is making that dream come true.

Understanding 3D printing in fashion

Understanding 3D printing in fashion is crucial for anyone interested in the future of the industry. This technology is changing how designers create garments. Instead of traditional methods, which can be time-consuming and less flexible, 3D printing allows for rapid prototyping and incredible customization.

This innovative approach not only saves time but also empowers creativity. With 3D printing, designers can bring their visions to life quickly and more precisely than ever before.

How 3D Printing Works

The process of 3D printing involves several steps that are fascinating and highly technical. First, a digital model is created using computer-aided design (CAD) software. Following this, the printer uses various materials, such as plastic or fabric, to build the item layer by layer.

This method greatly reduces waste compared to traditional fabric cutting. 3D printing in fashion utilizes only the materials needed, making it a more sustainable choice.

Advantages of 3D Printing in Fashion

- Customization: Each piece can be tailored to fit individual preferences and body shapes.

- Speed: Designers can create prototypes in days, not weeks.

- Sustainability: Reduces waste by using precise amounts of material.

- Innovation: Allows for creative designs that would be difficult to achieve by hand.

Moreover, 3D printing enables designers to explore new forms and concepts. It breaks down the barriers of conventional fashion, allowing for a level of customization and uniqueness that has not been possible before. Can you imagine wearing a dress that perfectly fits your body and reflects your style, made from a design you’ve conceptualized? This is now a reality.

As technology continues to advance, the potential applications in fashion are endless. From accessories to entire outfits, the possibilities are limited only by imagination. Designers are not just creating clothes; they are creating experiences that resonate with personal identity and innovation.

Benefits of 3D printing for custom designs

The benefits of 3D printing for custom designs are numerous and exciting. This technology revolutionizes the way designers create fashion pieces. From faster prototyping to complete customization, the advantages are clear.

One major benefit is speed. Traditional design methods can take weeks or even months. But with 3D printing, designers can produce prototypes in just a few days. This rapid turnaround allows for quicker feedback and adjustments.

Customization Options

Another advantage is the level of customization. With 3D printing, designers can easily create pieces tailored to individual customer preferences. Personalized sizes, colors, and designs become attainable without extra effort.

- Unique Styles: Each piece can reflect personal styles and needs.

- Variety of Materials: From plastics to fabrics, designers can use diverse materials.

- Exclusive Features: Create one-of-a-kind elements that stand out.

Additionally, 3D printing reduces waste significantly. Traditional manufacturing often results in leftover materials that go unused. In contrast, 3D printing uses only what is necessary to build items, enhancing sustainability.

This method also allows for intricate designs that are difficult or impossible to achieve through conventional techniques. Designers can experiment with complex shapes and structures, expanding their creative boundaries. Imagine a shoe with a unique heel design or a dress featuring elaborate patterns that fit perfectly.

Finally, the cost efficiency of 3D printing becomes noticeable. While initial investments in technology may be high, the long-term savings on materials and production time make it worthwhile. As production scales, costs decrease, making custom fashion more accessible.

How 3D printing enhances sustainability in fashion

How 3D printing enhances sustainability in fashion is an important consideration for modern designers. This technology offers notable solutions to traditional fashion’s environmental challenges.

One major way it enhances sustainability is through reduced waste. Traditional fashion manufacturing often produces a large amount of leftover fabric. In contrast, 3D printing uses only the exact materials needed to create each piece, minimizing excess waste.

Material Efficiency

Another benefit is material efficiency. Designers can select sustainable materials for printing, such as recycled plastics or biodegradable options. This focus on eco-friendly materials helps lessen the ecological impact.

- Eco-friendly materials: Many new materials are made from renewable sources.

- Reduced water usage: 3D printing requires significantly less water than traditional fabric dyeing methods.

- Local production: Makes it possible to produce items closer to consumers, cutting down on transportation emissions.

Moreover, 3D printing allows for on-demand production. This means products can be made as needed, reducing the need for large inventories and the risk of overproduction. Fashion brands can respond quickly to trends without creating excess stock that might end up in landfills.

In addition to being more sustainable, this approach also encourages innovation. Designers can experiment with complex designs that were previously impossible, utilizing materials in creative ways that enhance both aesthetic appeal and sustainability.

Ultimately, the integration of 3D printing in the fashion industry represents a shift towards a more sustainable future. It encourages responsible consumption, supports eco-friendly processes, and promotes a new style of production that benefits both creators and consumers.

Case studies of brands using 3D printing

Case studies of brands using 3D printing showcase the transformative impact this technology has on the fashion industry. Many companies have embraced 3D printing to push the boundaries of design and efficiency.

One notable example is Adidas. The brand introduced a line of shoes called Futurecraft, which uses 3D printing to create custom midsoles. This method allows for a perfect fit and enhanced comfort. Customers can get shoes tailored specifically to their feet, providing a unique experience that traditional manufacturing cannot match.

Another example is Nike

Nike has also jumped into the 3D printing space with its innovative Airsole technology. By using 3D printing, Nike can produce lighter, more flexible footwear. This process contributes to better performance for athletes while reducing the materials used in production.

- Adaptive Designs: Both Adidas and Nike are able to test multiple designs quickly without lengthy delays.

- On-Demand Manufacturing: These brands create shoes only as needed, minimizing waste.

- Rapid Prototyping: Concepts can be turned into physical products in days.

A smaller brand, like Nervous System, exemplifies the combination of 3D printing and artistic creativity. They produce jewelry and fashion accessories that feature intricate designs impossible to achieve through traditional means. Their use of 3D printing allows them to focus on small-batch production and unique customer requests, which fosters a strong connection with their audience.

Moreover, brands such as FDM (Fusion Deposition Modeling) utilize 3D printing to print garments directly from digital files. This process eliminates the need for many traditional steps in clothing production, leading to faster turnaround times and less environmental impact.

The movement towards adopting 3D printing has opened new avenues for brands of all sizes. By leveraging this technology, they can innovate while also addressing sustainability concerns in their production processes.

Future trends in 3D printing for fashion

Future trends in 3D printing for fashion look promising and are set to transform the industry even further. As technology advances, we can expect exciting developments that will shape how clothing is designed and manufactured.

One of the most significant trends is the rise of smart textiles. These fabrics incorporate technology that allows them to change color or adapt to different environments. With 3D printing, creating complex designs that integrate these smart textiles will become easier, making clothing more interactive and functional.

Customization and Personalization

Another important trend is the increased focus on customization and personalization. Fashion brands will likely use 3D printing to offer customers unique pieces tailored to their preferences. Imagine a store where you can design your clothing style, fit, and fabric on the spot!

- On-demand production: Items will be made as needed, reducing waste.

- Unique styles: More options for individual tastes and body types.

- Faster prototyping: Design concepts can be tested and modified quickly.

Sustainability will also be at the forefront of future developments. As brands become more aware of their environmental impact, 3D printing offers a sustainable solution. It minimizes waste and utilizes eco-friendly materials, making it a go-to option for brands aiming for greener practices.

Moreover, advancements in materials will allow for greater experimentation. New biodegradable and recyclable materials will emerge, enabling designers to create not only stylish but also environmentally friendly clothing.

Finally, collaboration between technology companies and fashion brands will foster innovation. As both industries work together, we will see the emergence of wearable technology that blends style with practicality. This partnership could lead to breakthroughs in how consumers interact with fashion.

FAQ – Frequently Asked Questions about 3D Printing in Fashion

How does 3D printing reduce waste in fashion production?

3D printing minimizes waste by using only the exact amount of material needed for each item, unlike traditional methods that often create excess fabric.

What are the benefits of customization in 3D printed fashion?

Customization allows for unique designs tailored to individual customer preferences, ensuring better fit and personal expression.

How is sustainability enhanced by using 3D printing?

3D printing enhances sustainability by using eco-friendly materials and reducing material waste, making it a greener option for fashion brands.

What future trends can we expect from 3D printing in fashion?

Future trends include the rise of smart textiles, greater focus on personalization, and the use of innovative and sustainable materials in design.