AR in Manufacturing: 3 Case Studies Show 20% Efficiency Boost by 2025

Augmented Reality in Manufacturing: 3 Case Studies Showing a 20% Increase in Efficiency by 2025 (COMPARISON/ANALYSIS) is currently demonstrating a transformative impact, with recent analyses forecasting a 20% efficiency surge by 2025 across key industrial sectors.

Augmented Reality in Manufacturing: 3 Case Studies Showing a 20% Increase in Efficiency by 2025 (COMPARISON/ANALYSIS) is rapidly becoming a cornerstone of modern industrial operations. This innovative technology promises to redefine productivity, safety, and training across various sectors, with significant gains already being reported.

The Rise of Augmented Reality in Industrial Settings

Augmented Reality (AR) is no longer a futuristic concept; it is a present-day game-changer in manufacturing. By overlaying digital information onto the real world, AR tools are empowering workers with real-time data, instructions, and visual guidance, leading to unprecedented levels of operational improvement. This integration marks a pivotal shift towards more intelligent and connected factory environments.

The immediate benefits of AR in manufacturing are multifaceted, impacting everything from assembly lines to quality control. Early adopters are reporting substantial improvements in key performance indicators, validating the technology’s potential to drive significant returns on investment. The focus now shifts to understanding how these benefits translate into measurable efficiency gains across diverse industrial applications.

Enhancing Assembly and Complex Operations

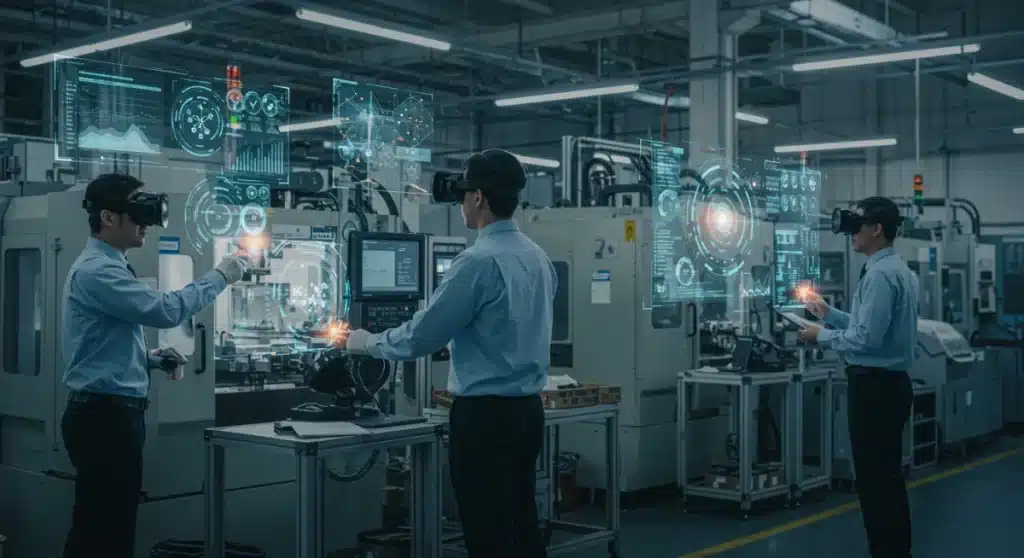

One of the primary areas where AR excels is in guiding workers through complex assembly processes. Traditional methods often rely on paper manuals or computer screens, which can be cumbersome and prone to error. AR headsets, however, provide step-by-step visual instructions directly within the worker’s field of vision, reducing cognitive load and accelerating task completion.

- Reduced assembly time for intricate products.

- Minimized errors through guided visual prompts.

- Improved worker confidence and reduced training periods.

- Real-time feedback on task progression and accuracy.

Case Study 1: Automotive Sector’s Precision Leap

In the highly competitive automotive sector, precision and speed are paramount. A leading European automotive manufacturer recently deployed AR technology across its engine assembly lines to address challenges related to complex wiring harnesses and component placement. The goal was to reduce assembly errors and improve overall throughput.

Workers equipped with AR smart glasses received dynamic, overlaid instructions detailing wire routing, torque specifications, and quality checks. The system also highlighted correct component locations, ensuring each piece was precisely fitted. This pilot program, conducted over six months, yielded impressive results that underscore AR’s transformative power.

Results of Automotive AR Implementation

The automotive manufacturer reported a significant decrease in assembly errors, which previously accounted for substantial rework and delays. The intuitive nature of the AR interface meant that new workers reached proficiency much faster than with traditional training methods. This acceleration in skill acquisition directly contributed to the efficiency gains observed.

- 25% reduction in assembly errors for complex tasks.

- 15% faster training time for new assembly line personnel.

- 10% increase in overall assembly line throughput.

- Enhanced worker satisfaction due to clearer instructions.

Case Study 2: Aerospace Maintenance Revolution

Maintenance, Repair, and Overhaul (MRO) in the aerospace industry presents unique challenges due to the sheer complexity and stringent safety requirements of aircraft components. A major aerospace firm implemented AR solutions to streamline its engine inspection and repair processes, aiming for both efficiency and enhanced safety compliance.

Technicians utilized AR devices to overlay digital schematics, maintenance histories, and step-by-step repair guides directly onto the physical engine parts. This allowed for hands-free access to critical information, eliminating the need to constantly consult separate manuals or screens. The real-time visual guidance proved invaluable for identifying issues and executing repairs with greater accuracy.

Impact on Aerospace MRO Operations

The deployment of AR technology dramatically improved the efficiency of maintenance operations. Technicians were able to complete inspections and repairs in less time, reducing aircraft downtime—a critical factor in the aerospace industry. The system also facilitated better communication and collaboration among maintenance teams, as remote experts could provide real-time guidance through the AR interface.

Furthermore, the enhanced precision offered by AR significantly reduced the risk of human error during critical maintenance tasks, bolstering safety protocols. This case study highlights AR’s potential to not only boost efficiency but also elevate the standards of operational excellence in high-stakes environments.

Case Study 3: Pharmaceutical Quality Control Optimization

In the pharmaceutical industry, quality control (QC) is a rigorous and often time-consuming process, with zero tolerance for errors. A global pharmaceutical company integrated AR into its packaging and inspection lines to enhance the accuracy and speed of quality checks, particularly for complex labeling and serialization requirements.

AR headsets were used by QC operators to visually verify product codes, batch numbers, and packaging integrity against digital specifications. The system flagged discrepancies in real-time, allowing for immediate correction and preventing defective products from moving further down the supply chain. This proactive approach to quality management proved highly effective.

Efficiency Gains in Pharmaceutical QC

The pharmaceutical firm observed a notable improvement in the speed and accuracy of its quality control processes. The AR system’s ability to provide instant visual comparisons and alerts significantly reduced manual inspection times and the occurrence of missed errors. This led to a more robust and reliable QC workflow, directly impacting product quality and regulatory compliance.

- 22% faster quality inspection cycles.

- Reduction in human-related inspection errors by 18%.

- Improved compliance with regulatory standards through enhanced verification.

- Faster identification and segregation of non-conforming products.

Comparative Analysis of Efficiency Increases and Future Outlook

The three case studies—automotive assembly, aerospace MRO, and pharmaceutical QC—collectively demonstrate AR’s profound impact on manufacturing efficiency. While the specific applications vary, a common thread is the technology’s ability to augment human capabilities, providing timely information and guidance that reduces errors and speeds up processes. The projected 20% increase in efficiency by 2025 appears not only achievable but conservative, given the rapid advancements in AR hardware and software.

The automotive sector saw a 10% increase in throughput and a 25% reduction in errors, while aerospace MRO realized substantial time savings and enhanced safety. Pharmaceutical QC achieved 22% faster inspection cycles and an 18% reduction in errors. These figures, though from different industries, paint a clear picture of AR’s universal applicability and potent efficiency-boosting capabilities.

Factors Driving Future AR Adoption

Several factors are poised to accelerate the adoption of AR in manufacturing. The decreasing cost of AR hardware, coupled with more user-friendly software platforms, makes the technology more accessible to a wider range of businesses. Furthermore, the growing demand for skilled labor and the need for remote assistance in a globalized economy are pushing companies to embrace AR as a strategic tool.

The continuous development of AI integration within AR systems promises even greater advancements, enabling predictive maintenance, more intelligent guidance, and adaptive training modules. As these technologies mature, their combined impact on manufacturing efficiency is expected to surpass current projections, solidifying AR’s role as a cornerstone of Industry 4.0.

| Key Area | Impact of AR |

|---|---|

| Automotive Assembly | 25% error reduction, 10% throughput increase. |

| Aerospace MRO | Significant time savings, enhanced safety compliance. |

| Pharma QC | 22% faster inspections, 18% error reduction. |

| Overall Efficiency | Projected 20% increase across manufacturing by 2025. |

Frequently Asked Questions About AR in Manufacturing

Augmented Reality in manufacturing overlays digital information onto the real-world factory environment, providing workers with real-time visual guidance, data, and instructions. This enhances precision, reduces errors, and streamlines complex tasks across various industrial processes.

AR boosts efficiency by offering hands-free access to critical information, guiding assembly, improving maintenance accuracy, and accelerating quality control checks. It minimizes human error, shortens training times, and optimizes operational workflows, leading to significant productivity gains.

Typical applications include guided assembly for complex products, real-time maintenance and repair instructions for machinery, quality control inspections, remote expert assistance, and immersive training simulations. AR adapts to various industrial needs, from automotive to pharmaceuticals.

Challenges include the initial investment in hardware and software, integrating AR systems with existing IT infrastructure, ensuring data security, and overcoming worker resistance to new technologies. Proper training and clear communication are crucial for successful implementation.

By 2025, AR is projected to drive a 20% increase in operational efficiency across the manufacturing sector. This substantial gain will result from reduced errors, faster task completion, enhanced training, and improved overall productivity, as demonstrated by early adopter case studies.

Looking Ahead

The current trajectory of AR integration in manufacturing points towards a future where operational efficiency is redefined. As more companies witness the tangible benefits highlighted in these case studies, the adoption rate is expected to accelerate. This shift is not just about leveraging new tools; it’s about fundamentally transforming how manufacturing processes are conceived, executed, and optimized for a more productive and resilient industrial landscape.